Example: H2 gas, 30 bar in, 500 bar out

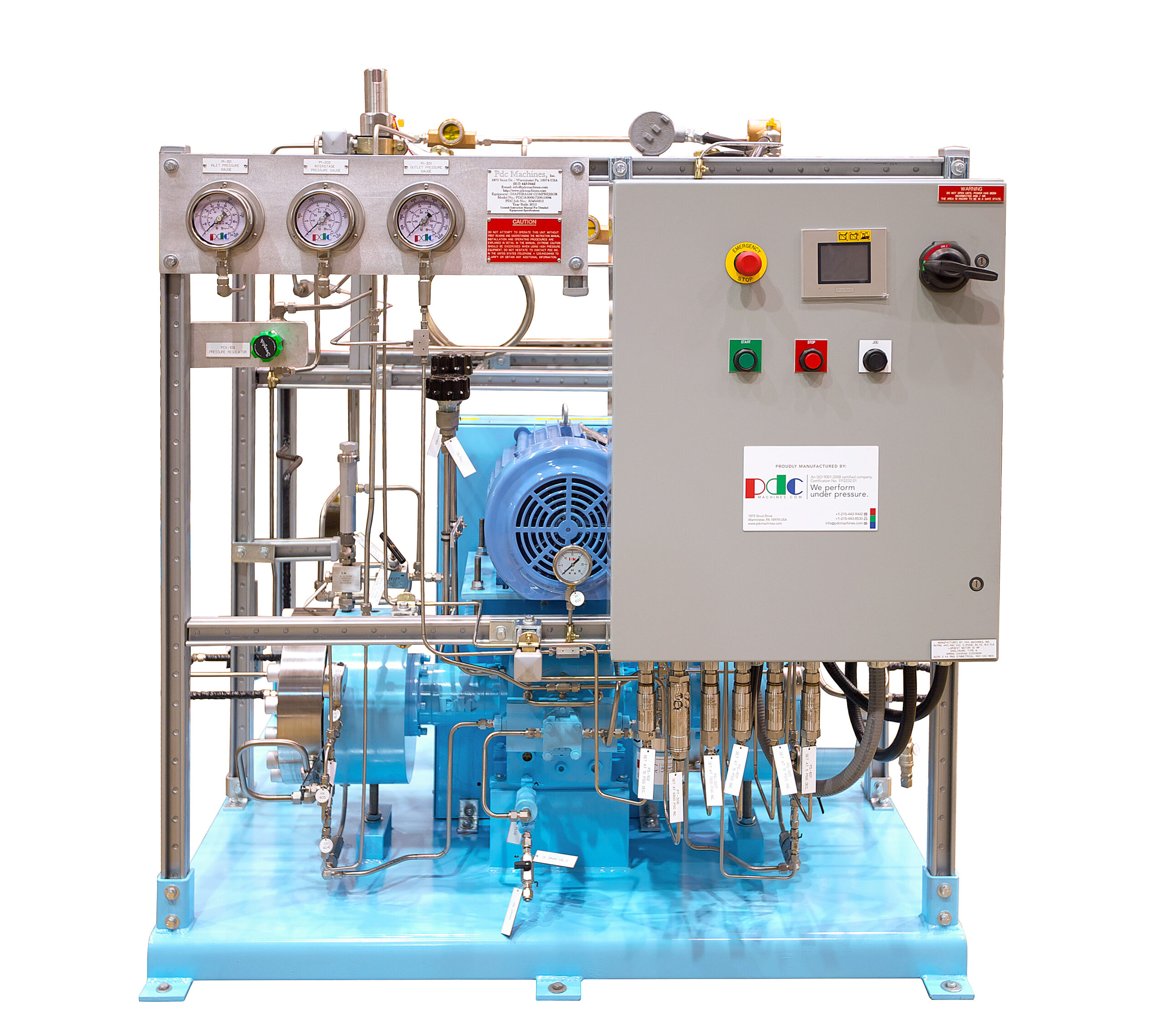

PDC-3: 50 kg/day

3' L x 3' W (1 x 1 M)

Single, two stage, or duplex configurations

Download BrochurePDC Machines has been manufacturing diaphragm compressors for industrial gas since 1977. We have developed an extensive line of PDC compressors and fully automated turnkey diaphragm process gas compressor systems with installations around the globe.

PDC-3

Example: H2 gas, 30 bar in, 500 bar out

PDC-3: 50 kg/day

3' L x 3' W (1 x 1 M)

Single, two stage, or duplex configurations

Download BrochurePDC-4

Example: H2 gas, 30 bar in, 500 bar out

PDC-4: 70-115 kg/day

6.5' L x 6.5' W (1.9 x 1.9 M)

Single, two stage, or duplex configurations

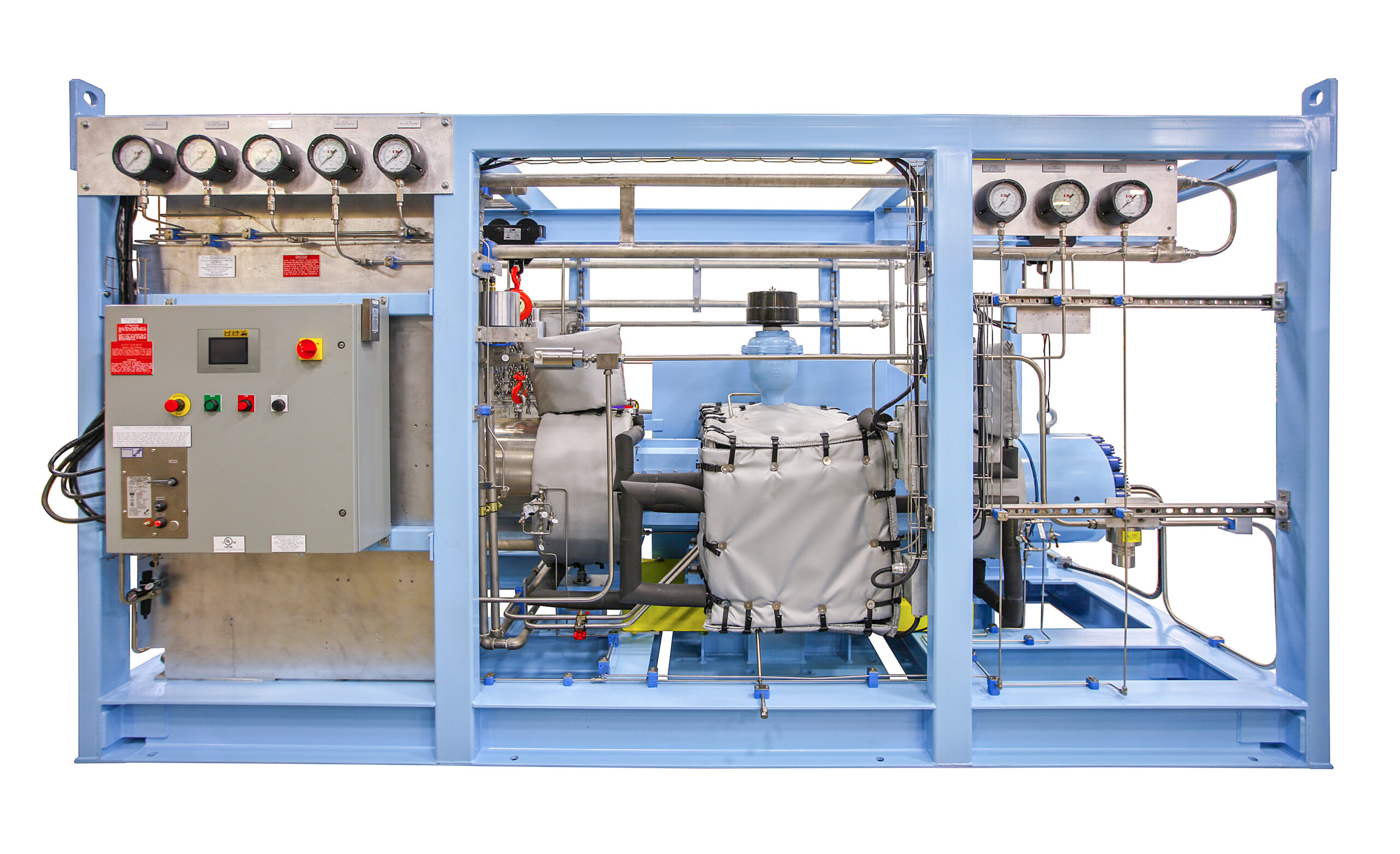

Download BrochurePDC-13

Example: H2 gas, 30 bar in, 500 bar out

PDC-13: 1000 kg/day

15' L x 8' W (4.5 x 2.4 M)

Single, two stage, or duplex configurations

Download BrochurePerformance Benefits

The triple diaphragm set ensures that the process gas is completely isolated from the hydraulic oil. PDC compressors do not use dynamic seals, eliminating potential seal particulate contamination. Filters and oil removal systems are not necessary – hydraulic oil cannot migrate into the process gas.

Performance Benefits

Our membrane metallic diaphragm compressors can achieve typical compression ratios up to 10:1 for certain models.

Performance Benefits

PDC compressors are capable of sub-atmospheric as well as high suction pressures. Our compressors are used in applications requiring low or high compression ratios, and in applications requiring intermittent or continuous service duty.

Performance Benefits

PDC compressors are completely instrumented for safe and automatic operation.

Maintenance and Reliability

All aspects of PDC’s diaphragm compressors enhance component life, improve operability, and reduce and simplify maintenance. Our diaphragm cavity contours, which control stress in the diaphragms, provide uniform stress distribution. PDC also uses special manufacturing processing on the diaphragm surfaces to enhance fatigue life. PDC customers experience continuous running times of 10,000 to 40,000 hours between routine maintenance, minimizing the need for spare parts replacement.

Maintenance and Reliability

To detect and indicate diaphragm and seal failure.

Maintenance and Reliability

PDC compressors typically only require routine oil changes.

Safety and Environmental

PDC compressors are completely instrumented for safe and automatic operation.

Safety and Environmental

PDC Diaphragm Compressors use non-flammable hydraulic fluid and all process-wetted components, which are constructed from corrosion-resistant materials for processing corrosive or oxidizing gases. This ensures safe operation and prolongs the life of maintenance components.

Safety and Environmental

Our diaphragm compressors use static seals. There is no migration of gas into the crankcase – as such, the crankcase does not require purging or venting. PDC compressors’ gas system integrity also prevents leakage of gas into the atmosphere.

Operation

PDC compressors are automatically reprimed at start-up. Manual start-up requires an experienced compressor technician to reprime the diaphragm compressor. Incorrect priming can cavitate the compressor and damage the heads, bolts, diaphragms, O-rings, process and hydraulic system. PDC Compressors avoid this potential issue with our cutting-edge repriming tech.

Operation

Below 85 dBA at 1 meter without sound-proofing enclosure.

Operation

PDC diaphragm compressors hydraulic systems are designed in such a way as to ensure uniform diaphragm deflection, prevent knocks, vibration, cavitation and yield smooth, and quiet compressor operation.

Operation

PDC compressors use a heavy flywheel to provide energy. In addition, Duplex and two-stage diaphragm compressors can be horizontally opposed to further reduce horsepower requirements and energy usage, resulting in ease of use and cost savings for the end user.

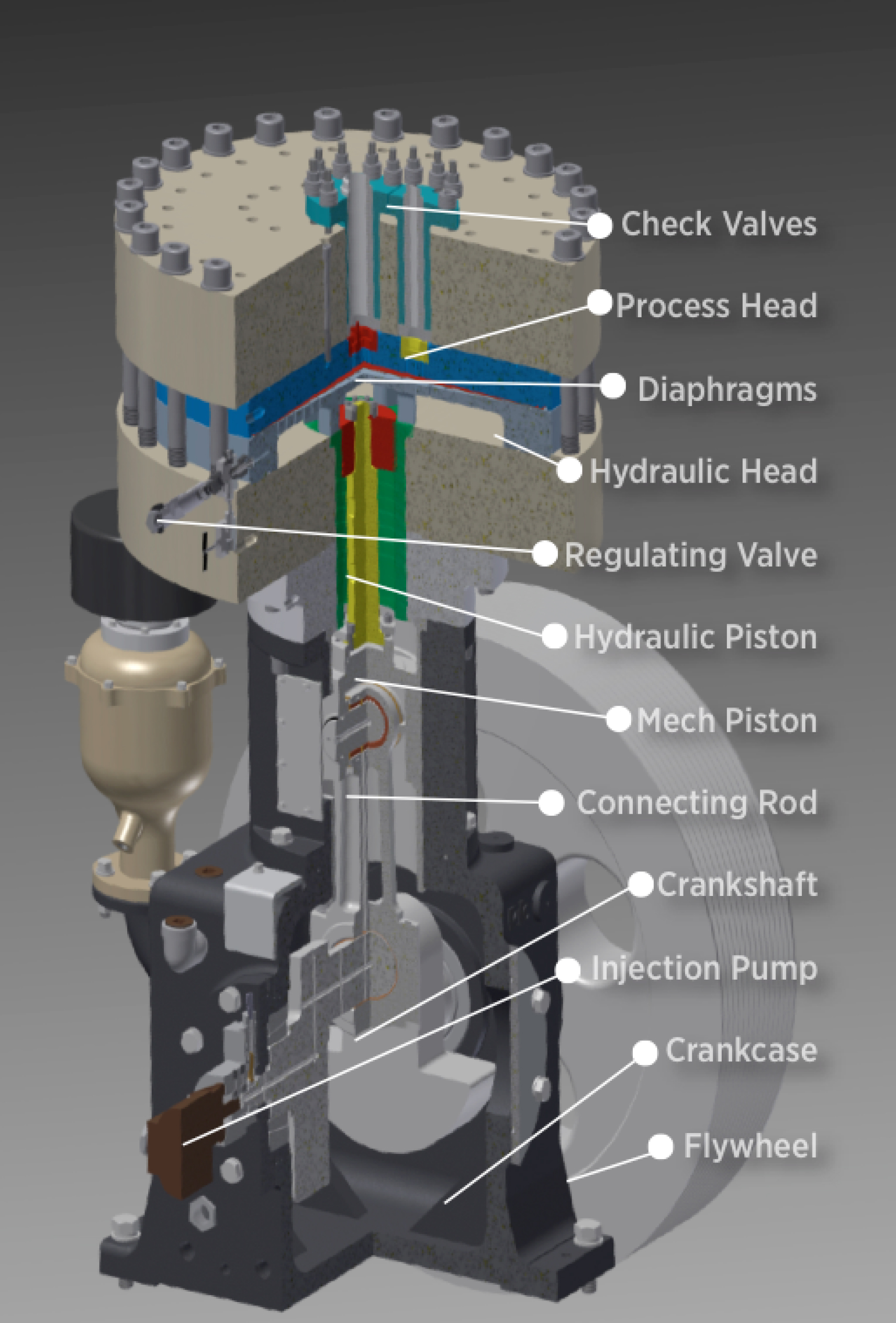

Diaphragm Compressors Explained

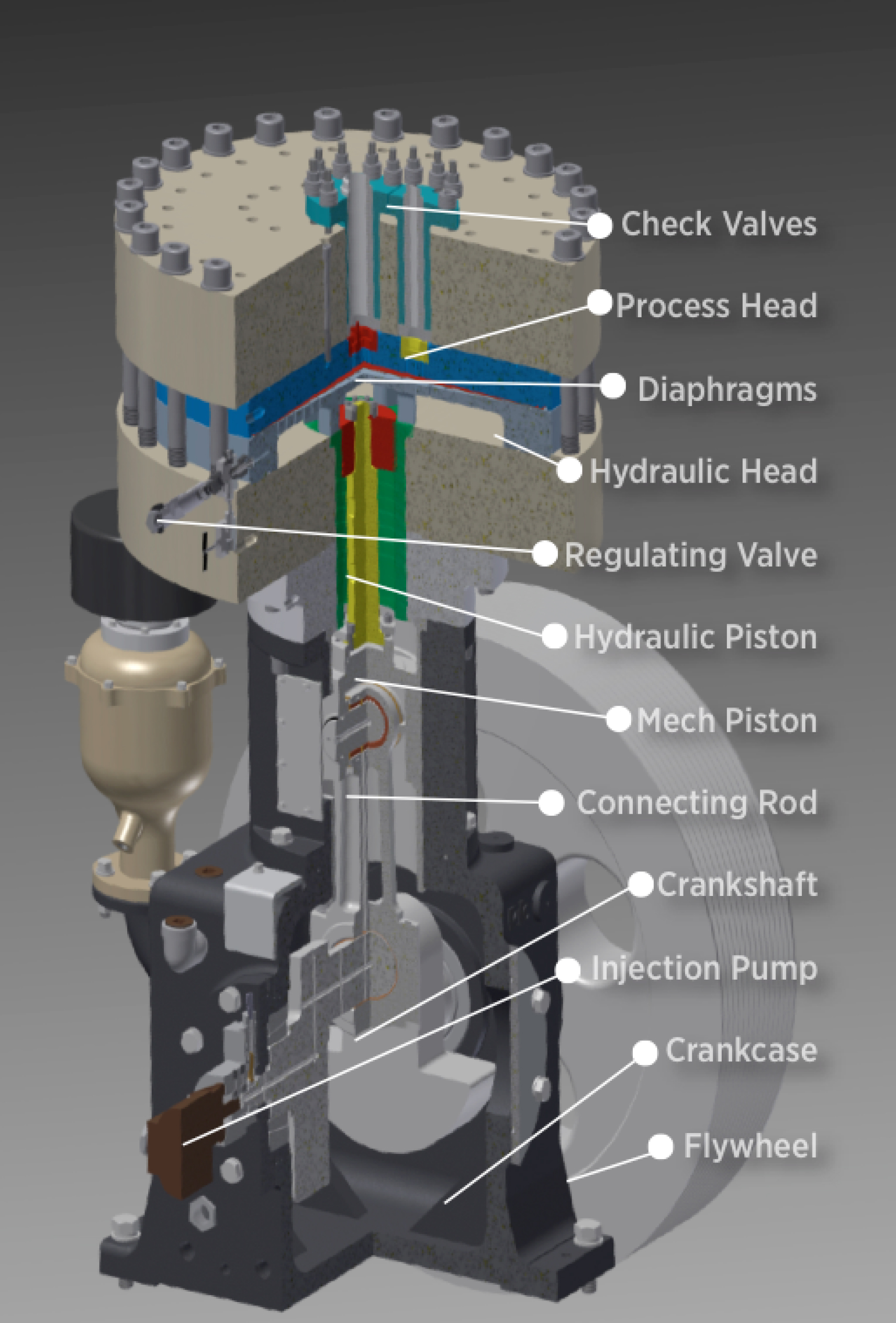

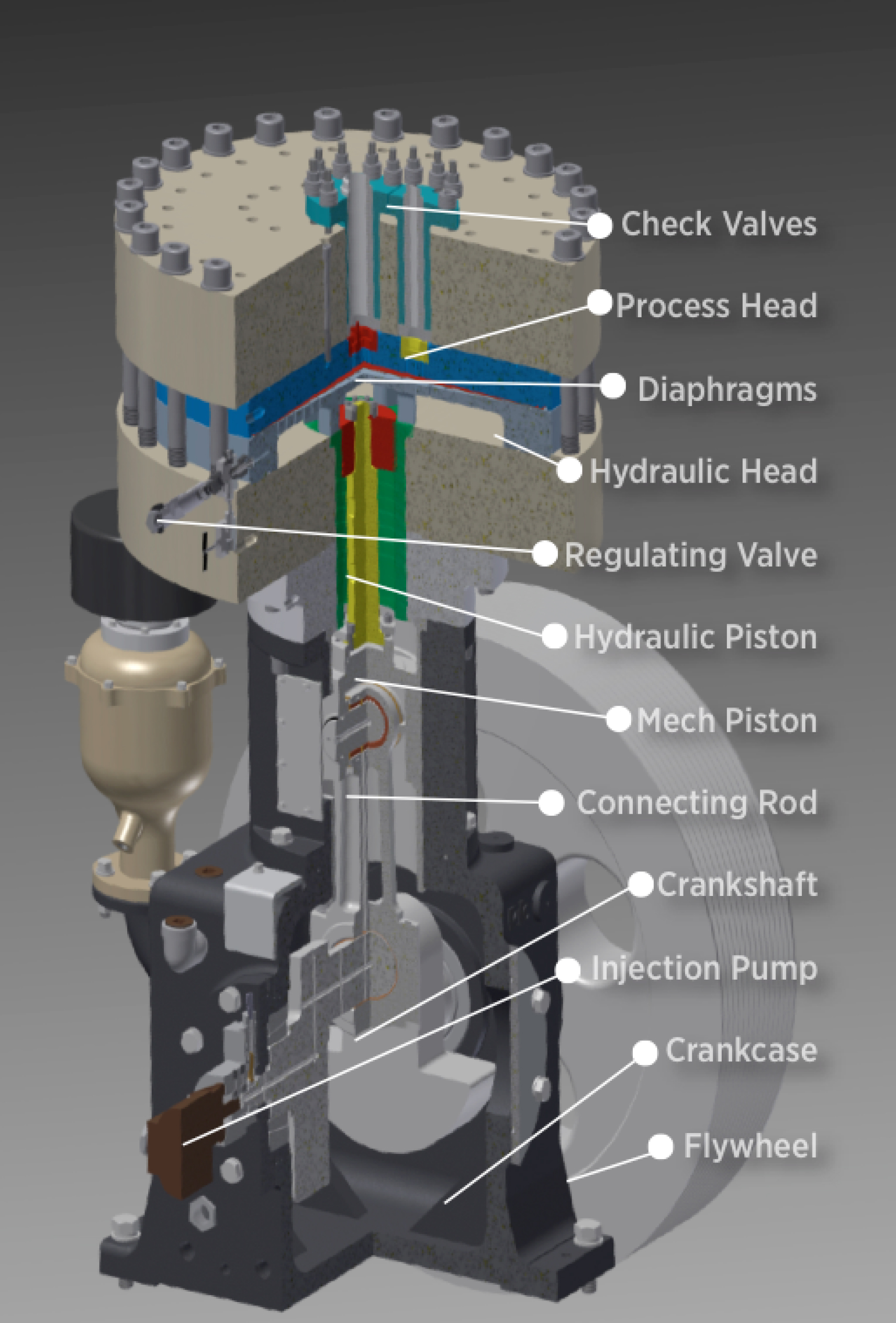

The oil regulating valve limits maximum hydraulic and gas pressure and ensures that the diaphragms completely “sweep” the upper and lower cavity contours to maximize displacement.

Diaphragm Compressors Explained

PDC Compressors provide a plunger-type injection system on all motor-driven diaphragm units. The injectors are also crank driven and precisely meter hydraulic fluid flow during the operation of the compressor.

Diaphragm Compressors Explained

The deflection and resultant stresses in PDC metal diaphragms are controlled by carefully designed cavity contours. We use state-of-the-art design and analysis tools as well as cutting-edge programs to model these.

Diaphragm Compressors Explained

At PDC Machines, we machine-process heads from a variety of materials for process gas compatibility. Our gold-standard process heads are constructed from 300 series stainless steel.

Diaphragm Compressors Explained

The diaphragm set consists of three plates. The upper or process side, the lower or hydraulic side and the middle diaphragm. The middle diaphragm is brass to preclude galling. The upper and lower are typically 301 series stainless steel for most applications. However, the upper diaphragm material can be supplied in alternate materials, such as Inconel 718, for process compatibility.

Diaphragm Compressors Explained

We offer an extensive variety of static elastomeric O-ring seals for process gas compatibility. Options include Buna-N, Viton, and Teflon-encapsulated Viton and Kalrez.

Diaphragm Compressors Explained

Included with every PDC diaphragm compressor is a leak detection system. This system detects diaphragm or seal failures. Our leak detection system monitors the gas and hydraulic sides of the compressor and will sound an alarm and/or shut down the compressor when it detects an anomaly or failure. Proper maintenance, operation, and clean/dry process gas prolongs component operating life.

Diaphragm Compressors Explained

Compressor process check valve design depends on operating conditions and the process gas itself. PDC compressors typically utilize cartridge- or plate-style check valves. PDC designs valves and valve pockets for easy removal and maintenance.

Diaphragm Compressors Explained

PDC compressors are automatically reprimed at start-up and unloaded upon shutdown. This process is an important procedure that not only provides for maximum efficiency but also eliminates the need for an operator to start up or reprime the compressor.

Diaphragm Compressors Explained

Our hydraulic systems are designed to ensure uniform diaphragm deflection, prevent knocks, vibration, and cavitation, and yield smooth, quiet compressor operation. We employ unique oil distribution techniques to eliminate pressure differentials and gradients. The system utilizes an automatic priming pump, positive displacement high-pressure injection pump, and oil relief valve with bypass valve for smooth, easy starting.

Quality

PDC’s diaphragm compressors can be designed and certified to comply with Canadian, European, South Korean, Japanese, United States, Korean, Chinese, and other international codes and standards.

Quality

PDC has an ISO 9001:2015 certified quality management system.

Quality

All diaphragm compressors are mechanically run and performance is tested for eight hours.

Diaphragm Compressors Explained

All

Performance Benefits

The triple diaphragm set ensures that the process gas is completely isolated from the hydraulic oil. PDC compressors do not use dynamic seals, eliminating potential seal particulate contamination. Filters and oil removal systems are not necessary – hydraulic oil cannot migrate into the process gas.

Performance Benefits

Our membrane metallic diaphragm compressors can achieve typical compression ratios up to 10:1 for certain models.

Performance Benefits

PDC compressors are capable of sub-atmospheric as well as high suction pressures. Our compressors are used in applications requiring low or high compression ratios, and in applications requiring intermittent or continuous service duty.

Performance Benefits

PDC compressors are completely instrumented for safe and automatic operation.

Maintenance and Reliability

All aspects of PDC’s diaphragm compressors enhance component life, improve operability, and reduce and simplify maintenance. Our diaphragm cavity contours, which control stress in the diaphragms, provide uniform stress distribution. PDC also uses special manufacturing processing on the diaphragm surfaces to enhance fatigue life. PDC customers experience continuous running times of 10,000 to 40,000 hours between routine maintenance, minimizing the need for spare parts replacement.

Maintenance and Reliability

To detect and indicate diaphragm and seal failure.

Maintenance and Reliability

PDC compressors typically only require routine oil changes.

Safety and Environmental

PDC compressors are completely instrumented for safe and automatic operation.

Safety and Environmental

PDC Diaphragm Compressors use non-flammable hydraulic fluid and all process-wetted components, which are constructed from corrosion-resistant materials for processing corrosive or oxidizing gases. This ensures safe operation and prolongs the life of maintenance components.

Safety and Environmental

Our diaphragm compressors use static seals. There is no migration of gas into the crankcase – as such, the crankcase does not require purging or venting. PDC compressors’ gas system integrity also prevents leakage of gas into the atmosphere.

Operation

PDC compressors are automatically reprimed at start-up. Manual start-up requires an experienced compressor technician to reprime the diaphragm compressor. Incorrect priming can cavitate the compressor and damage the heads, bolts, diaphragms, O-rings, process and hydraulic system. PDC Compressors avoid this potential issue with our cutting-edge repriming tech.

Operation

Below 85 dBA at 1 meter without sound-proofing enclosure.

Operation

PDC diaphragm compressors hydraulic systems are designed in such a way as to ensure uniform diaphragm deflection, prevent knocks, vibration, cavitation and yield smooth, and quiet compressor operation.

Operation

PDC compressors use a heavy flywheel to provide energy. In addition, Duplex and two-stage diaphragm compressors can be horizontally opposed to further reduce horsepower requirements and energy usage, resulting in ease of use and cost savings for the end user.

Diaphragm Compressors Explained

The oil regulating valve limits maximum hydraulic and gas pressure and ensures that the diaphragms completely “sweep” the upper and lower cavity contours to maximize displacement.

Diaphragm Compressors Explained

PDC Compressors provide a plunger-type injection system on all motor-driven diaphragm units. The injectors are also crank driven and precisely meter hydraulic fluid flow during the operation of the compressor.

Diaphragm Compressors Explained

The deflection and resultant stresses in PDC metal diaphragms are controlled by carefully designed cavity contours. We use state-of-the-art design and analysis tools as well as cutting-edge programs to model these.

Diaphragm Compressors Explained

At PDC Machines, we machine-process heads from a variety of materials for process gas compatibility. Our gold-standard process heads are constructed from 300 series stainless steel.

Diaphragm Compressors Explained

The diaphragm set consists of three plates. The upper or process side, the lower or hydraulic side and the middle diaphragm. The middle diaphragm is brass to preclude galling. The upper and lower are typically 301 series stainless steel for most applications. However, the upper diaphragm material can be supplied in alternate materials, such as Inconel 718, for process compatibility.

Diaphragm Compressors Explained

We offer an extensive variety of static elastomeric O-ring seals for process gas compatibility. Options include Buna-N, Viton, and Teflon-encapsulated Viton and Kalrez.

Diaphragm Compressors Explained

Included with every PDC diaphragm compressor is a leak detection system. This system detects diaphragm or seal failures. Our leak detection system monitors the gas and hydraulic sides of the compressor and will sound an alarm and/or shut down the compressor when it detects an anomaly or failure. Proper maintenance, operation, and clean/dry process gas prolongs component operating life.

Diaphragm Compressors Explained

Compressor process check valve design depends on operating conditions and the process gas itself. PDC compressors typically utilize cartridge- or plate-style check valves. PDC designs valves and valve pockets for easy removal and maintenance.

Diaphragm Compressors Explained

PDC compressors are automatically reprimed at start-up and unloaded upon shutdown. This process is an important procedure that not only provides for maximum efficiency but also eliminates the need for an operator to start up or reprime the compressor.

Diaphragm Compressors Explained

Our hydraulic systems are designed to ensure uniform diaphragm deflection, prevent knocks, vibration, and cavitation, and yield smooth, quiet compressor operation. We employ unique oil distribution techniques to eliminate pressure differentials and gradients. The system utilizes an automatic priming pump, positive displacement high-pressure injection pump, and oil relief valve with bypass valve for smooth, easy starting.

Quality

PDC’s diaphragm compressors can be designed and certified to comply with Canadian, European, South Korean, Japanese, United States, Korean, Chinese, and other international codes and standards.

Quality

PDC has an ISO 9001:2015 certified quality management system.

Quality

All diaphragm compressors are mechanically run and performance is tested for eight hours.

Diaphragm Compressors Explained

Safety and Environmental

Safety and Environmental

PDC compressors are completely instrumented for safe and automatic operation.

Safety and Environmental

PDC Diaphragm Compressors use non-flammable hydraulic fluid and all process-wetted components, which are constructed from corrosion-resistant materials for processing corrosive or oxidizing gases. This ensures safe operation and prolongs the life of maintenance components.

Safety and Environmental

Our diaphragm compressors use static seals. There is no migration of gas into the crankcase – as such, the crankcase does not require purging or venting. PDC compressors’ gas system integrity also prevents leakage of gas into the atmosphere.

Maintenance and Reliability

Maintenance and Reliability

All aspects of PDC’s diaphragm compressors enhance component life, improve operability, and reduce and simplify maintenance. Our diaphragm cavity contours, which control stress in the diaphragms, provide uniform stress distribution. PDC also uses special manufacturing processing on the diaphragm surfaces to enhance fatigue life. PDC customers experience continuous running times of 10,000 to 40,000 hours between routine maintenance, minimizing the need for spare parts replacement.

Maintenance and Reliability

To detect and indicate diaphragm and seal failure.

Maintenance and Reliability

PDC compressors typically only require routine oil changes.

Performance Benefits

Performance Benefits

The triple diaphragm set ensures that the process gas is completely isolated from the hydraulic oil. PDC compressors do not use dynamic seals, eliminating potential seal particulate contamination. Filters and oil removal systems are not necessary – hydraulic oil cannot migrate into the process gas.

Performance Benefits

Our membrane metallic diaphragm compressors can achieve typical compression ratios up to 10:1 for certain models.

Performance Benefits

PDC compressors are capable of sub-atmospheric as well as high suction pressures. Our compressors are used in applications requiring low or high compression ratios, and in applications requiring intermittent or continuous service duty.

Performance Benefits

PDC compressors are completely instrumented for safe and automatic operation.

Operation

Operation

PDC compressors are automatically reprimed at start-up. Manual start-up requires an experienced compressor technician to reprime the diaphragm compressor. Incorrect priming can cavitate the compressor and damage the heads, bolts, diaphragms, O-rings, process and hydraulic system. PDC Compressors avoid this potential issue with our cutting-edge repriming tech.

Operation

Below 85 dBA at 1 meter without sound-proofing enclosure.

Operation

PDC diaphragm compressors hydraulic systems are designed in such a way as to ensure uniform diaphragm deflection, prevent knocks, vibration, cavitation and yield smooth, and quiet compressor operation.

Operation

PDC compressors use a heavy flywheel to provide energy. In addition, Duplex and two-stage diaphragm compressors can be horizontally opposed to further reduce horsepower requirements and energy usage, resulting in ease of use and cost savings for the end user.

Diaphragm Compressors Explained

Diaphragm Compressors Explained

The oil regulating valve limits maximum hydraulic and gas pressure and ensures that the diaphragms completely “sweep” the upper and lower cavity contours to maximize displacement.

Diaphragm Compressors Explained

PDC Compressors provide a plunger-type injection system on all motor-driven diaphragm units. The injectors are also crank driven and precisely meter hydraulic fluid flow during the operation of the compressor.

Diaphragm Compressors Explained

The deflection and resultant stresses in PDC metal diaphragms are controlled by carefully designed cavity contours. We use state-of-the-art design and analysis tools as well as cutting-edge programs to model these.

Diaphragm Compressors Explained

At PDC Machines, we machine-process heads from a variety of materials for process gas compatibility. Our gold-standard process heads are constructed from 300 series stainless steel.

Diaphragm Compressors Explained

The diaphragm set consists of three plates. The upper or process side, the lower or hydraulic side and the middle diaphragm. The middle diaphragm is brass to preclude galling. The upper and lower are typically 301 series stainless steel for most applications. However, the upper diaphragm material can be supplied in alternate materials, such as Inconel 718, for process compatibility.

Diaphragm Compressors Explained

We offer an extensive variety of static elastomeric O-ring seals for process gas compatibility. Options include Buna-N, Viton, and Teflon-encapsulated Viton and Kalrez.

Diaphragm Compressors Explained

Included with every PDC diaphragm compressor is a leak detection system. This system detects diaphragm or seal failures. Our leak detection system monitors the gas and hydraulic sides of the compressor and will sound an alarm and/or shut down the compressor when it detects an anomaly or failure. Proper maintenance, operation, and clean/dry process gas prolongs component operating life.

Diaphragm Compressors Explained

Compressor process check valve design depends on operating conditions and the process gas itself. PDC compressors typically utilize cartridge- or plate-style check valves. PDC designs valves and valve pockets for easy removal and maintenance.

Diaphragm Compressors Explained

PDC compressors are automatically reprimed at start-up and unloaded upon shutdown. This process is an important procedure that not only provides for maximum efficiency but also eliminates the need for an operator to start up or reprime the compressor.

Diaphragm Compressors Explained

Our hydraulic systems are designed to ensure uniform diaphragm deflection, prevent knocks, vibration, and cavitation, and yield smooth, quiet compressor operation. We employ unique oil distribution techniques to eliminate pressure differentials and gradients. The system utilizes an automatic priming pump, positive displacement high-pressure injection pump, and oil relief valve with bypass valve for smooth, easy starting.

Diaphragm Compressors Explained

Quality

Quality

PDC’s diaphragm compressors can be designed and certified to comply with Canadian, European, South Korean, Japanese, United States, Korean, Chinese, and other international codes and standards.

Quality

PDC has an ISO 9001:2015 certified quality management system.

Quality

All diaphragm compressors are mechanically run and performance is tested for eight hours.

If you are trying to understand why people use diaphragm compressors, then you have come to the right place.

In this article, we will explore the advantages of diaphragm compressors and why they are the preferred choice for many industries. We will also examine the different types of diaphragm compressors and the components of these compressors.

Finally, we will discuss the differences between air and oil-lubricated cylinder head piston or connecting rod compressors and why you should opt for the former over the latter type products.

By the end of this post, you will have better information and understanding of why people use diaphragm compressors and why they are the best technology choice for many applications versus generators to create the gasses onsite.

A diaphragm compressor uses a set of flexible, rotating membranes to compress gas in a chamber. This design is particularly effective for compressing toxic or explosive gasses, because metal-to-metal friction is kept to a minimum.

All PDC company sealless reciprocating diaphragm compressors meet API 618 standards and specifications for non- contaminating gas compression products, so you can rest assured your gas is protected from contamination. They also offer long durability, high capacity and trouble free operation with regular maintenance. Call for a quote on our gas compression products and services.

A diaphragm compressor compresses air using a set of flexible membranes that deflect back and forth. The membrane is driven by a rod and crankshaft mechanism that motivates the diaphragm to move up and down, displacing gas in the process head and compressing it to be sent on to the desired application.

As the piston moves down and toward bottom-dead-center (BDC), it creates a higher internal pressure than the external pressure of the process gas inside the cavity. The membrane then sweeps up to TDC, reducing the pressure in the cavity.

Diaphragm compressors are characterized by a high compression ratio, good sealing performance and are resistant to lubricating oil and solid impurities, an example are the PDC industrial diaphragm compressor products. They are particularly suitable for compressed gasses of the highest purity as well as explosive and toxic gasses.

Diaphragm air compressors use three elongated, flexible membranes that flex on the down- stroke of the pump to draw in and compress air from outside the process. As the compressor cycles on its up-stroke, the membranes flex again to reduce the chamber size and compress the gas.

A diaphragm compressor is a type of reciprocating compressor with a back-and-forth moving membrane instead of an intake element. The construction of a diaphragm compressor is ideal for pumping explosive and toxic gasses because it prevents hydraulic fluid from coming in contact with the process gas.

The crankshaft and connecting rod mechanism powers the reciprocating diaphragm. During the compressor cycle, the compressor box and the diaphragm come in touch with the pumped fluid (gas or air).

To begin the compression process, the piston ring is pushed toward the BDC. Then, the diaphragm sweeps the cavity towards the Top-Dead-Center position, compressing the process gas. The process gas enters the compression chamber through a check valve and the suction pressure is reduced by the diaphragm.

The oil then helps the membrane flex upward and downward, thereby compressing air or gas inside the cavity. As the internal pressure of the gas goes higher than the external gas pressure, the valve closes and the compression process is complete. The cycle repeats and the compressor continues to operate.

Diaphragm compressors are a type of air compressor that uses a set of diaphragm membranes to compress gas. The membranes are flexed on the downstroke and compressed on the upstroke. This process allows the compressor to apply a high level of pressure on the gas being compressed.

Another benefit of using a diaphragm compressor is that it can save energy. This is important since it can help reduce overall energy costs in 24/7 industrial applications.

This type of compressor is best for handling toxic or explosive gasses. It is also a good choice for treating radioactive or inert gasses.

However, you need to make sure that you choose the right compressor for your application. It must be reliable enough to support the strain of pumped gas and it should have the necessary heat resistance and chemical properties.

The chance of seal failure when using a diaphragm compressor is extremely low. However, there are a few things you should be aware of.

One of the most important is selecting a diaphragm seal made of the right material. This can make a huge difference in performance, especially when used in corrosive environments.

Another thing to consider is the type of fill fluid that you use. A proper fill fluid for your specific application is essential to keep the seal lubricated, preventing the formation of hydrogen bubbles that may damage the seal.

Lastly, choosing the right size seal is crucial. It is a good idea to look for a seal that will fit your compressor’s dimensions and allow the flow of the required amount of fill fluid.

The chances of a seal failing are small, but the risk of leaks is still there. The best way to avoid this is to do regular maintenance and ensure that the proper seal is in place.

If you are having trouble with your diaphragm compressor, it is a good idea to consult with an expert about what needs to be done. Long-term, this will save you both time and money.

There are several different types of diaphragm compressors available on the market today, each with its own set of advantages and disadvantages. It is important to consider all factors when selecting a compressor for your specific needs – from cost comparisons to maintenance tips.

With this knowledge in hand, you can make an informed decision that will help you get the most out of your diaphragm compressor. Now it is time to take action! Get started by contacting the diaphragm compressor manufacturing experts at PDC Machines and finding one that meets your needs and budget.

Get in Touch