Tools

At PDC Machines, our aim is to set our customers up for success. We go the extra mile to provide expert guidance to our customers well past the point of purchase, and through the life cycle of equipment delivered. We offer unrivaled after sales support, working closely with our customers to ensure proper and safe operation of PDC’s compressors. We also provide maintenance and service training, offering both remote and on-site assistance.

Introducing the PDC Toolbox, a collection of tools developed specifically for PDC compressors, to optimize in-house service and maintenance. The PDC toolbox was developed as an extension of our unique aftermarket offering, to put the tools for success in our customer’s hands, literally!

All tools come with an instruction manual to ensure proper use.

To learn more:

Gauge Tree

Used to set the compressor’s oil relief valve (ORV) dynamically. The Gauge Tree comes in different pressure ranges, pressure gauge & connection type will vary.

Function

The compressor’s ORV maintains hydraulic pressure for each head. Typical replacement schedule is 8k hrs. Replacement valves must be set dynamically using this tool to ensure proper configuration.

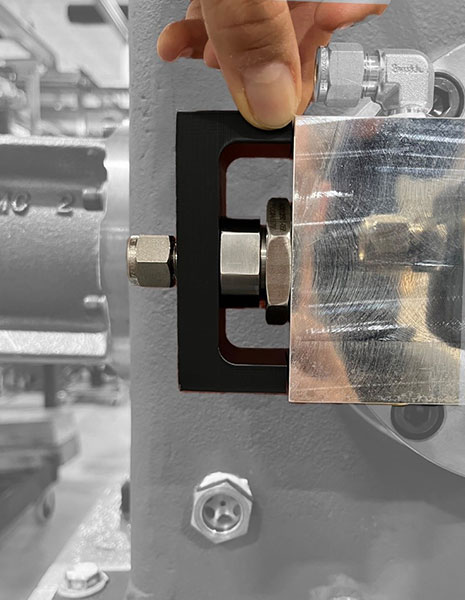

Injector Block Setting Tool

Ensures injector depths are set to factory specification following any service or maintenance.

Function

This tool is required to allow proper oil flow. Failure to set properly may result in loss of oil and failed major components.

Process Head Guide Pins

Ensures safely aligned separation of the process and hydraulic head during preventative maintenance. The guide pins allow for ample space to change diaphragms and O-rings without an overhead lift which eases serviceability.

Function

Utilizing the Guide Pins, service professionals can safely separate the heads without risk of the heads swinging into each other. A crane may still be used, but these allow safe alignment.

CV Removal & Cleaning Tool

Aids service professionals in removing the process check valves installed deep in the process head.

Function

The CV removal tool includes an application specific interface for the valves in each PDC compressor. The same tool interface can be swapped to the cleaning head to remove any stubborn elastomer residue in the check valve cavity.

Cleaning Kit

Includes all the typical cleaning, abrasives, PPE and sealants necessary to ensure a clean and debris-free compressor.

Function

A recommended add on to any maintenance kit, the Cleaning Kit will take the guess work out of preparing for that next service. Let PDC supply the necessary consumables, in the necessary quantity for your upcoming service.